Fleet Management Weekly asked Gina Bonini, VP and GM of Advanced Thermal Systems at Modine, about the challenges of keeping Electric Vehicles (EVs) up and running in wintry weather.

Modine is a company with a long history of automotive thermal management; how did you make the transition from ICE to EV?

Modine has focused on innovation in thermal management from the company’s beginning in 1916, when our founder, Arthur B. Modine, set out to make the perfect radiator. A few years later, in 1925, we scaled up to provide the radiator for the Model T Ford. Fast forward nearly 100 years, and we started to see our customers electrifying, initially with buses, trucks and specialty vehicles. We engaged with our customers to understand their thermal management needs for medium- and heavy-duty EVs, and in 2018 we began developing our battery thermal management system (BTMS) and electronics cooling package (ECP) for commercial EV use.

Both systems are in use today across transportation sectors. Modine’s EVantage™ line of thermal management systems, which regulates battery, traction motor, and power electronics temperatures in all operating conditions, launched earlier this year. Modine recently announced a partnership with The Shyft Group to supply customized thermal management systems to the Blue Arc™ all-electric last-mile delivery vehicle.

Both systems are in use today across transportation sectors. Modine’s EVantage™ line of thermal management systems, which regulates battery, traction motor, and power electronics temperatures in all operating conditions, launched earlier this year. Modine recently announced a partnership with The Shyft Group to supply customized thermal management systems to the Blue Arc™ all-electric last-mile delivery vehicle.

What commercial EV components require thermal management?

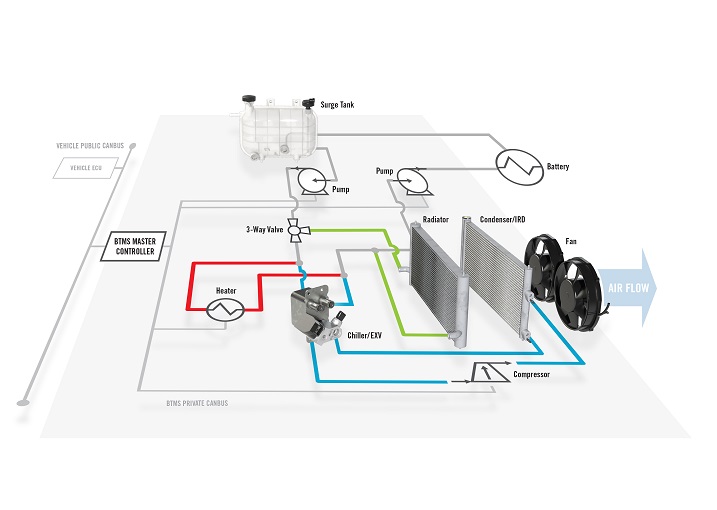

In commercial EVs, two main areas require careful consideration for thermal management – the battery pack and the power electronics. The battery pack needs to be maintained in a narrow window – typically 25 to 35°C – during charging and operation to preserve peak performance benchmarks like range and time to charge. A BTMS is commonly used to maintain the temperature of the battery pack. The power electronics – inverter, converter, and traction motor – will heat up as they operate and typically have a cooling package to maintain temperature and prevent long-term damage.

How does the battery thermal management system (BTMS) work?

The coolant that circulates in the battery pack will route through a BTMS to heat or cool as needed to maintain the battery pack in the desired temperature range. If outdoor temps are below 25°C, the BTMS heating loop will raise the temperature of the coolant. Once the vehicle is in operation, the batteries start generating heat that needs to be removed to keep the battery pack from overheating. The BTMS will then switch to using the cooling loop to take the heat out of the coolant. A BTMS may have two cooling loops: an active loop featuring a refrigerant circuit to remove heat in hotter temperatures and a passive loop featuring a radiator and fans if the ambient temperature is moderate, which draws less power to cool.

How do temperature swings affect EV batteries and battery performance?

How do temperature swings affect EV batteries and battery performance?

The longevity and performance of EV batteries depend heavily on stress factors like storage conditions and operating temperature. These factors can impact the battery’s capacity, safety, and working lifetime. Lower temperatures can reduce the capacity as the chemical reactions inside the battery slow down. For high temperatures, the chemical reactions in the battery speed up, draining the battery at a higher rate. If the battery is continually exposed to extreme temperatures, it can degrade over time.

A BTMS is designed to protect the battery from these stress factors as it helps maintain a battery pack at its optimal temperature regardless of harsh outdoor temperatures. This control improves charging time, optimizes range, and minimizes battery degradation.

Specifically, what happens to EV batteries in cold weather conditions?

Cold weather is known to impact EV battery range and performance. The vehicle’s range may be reduced by up to 40%, but it is important to know that nearly two-thirds of the range reduction is due to extra draw on the battery to heat the cabin for driver comfort. When less cabin heating is used, the range impacts are not as significant. Cold temperatures also impact battery performance as the battery will deplete a charge faster and take longer to recharge.

What can fleet owners do to prepare EV fleets ahead of winter?

Commercial electric vehicles should have a battery thermal management system in place that is designed to regulate battery temperature in a way that maximizes range and minimizes charging time. A BTMS will continue to do its job in cold weather, but there are a few specific ways fleet managers and drivers can help optimize their efficiency and uptime during the winter months.

Commercial electric vehicles should have a battery thermal management system in place that is designed to regulate battery temperature in a way that maximizes range and minimizes charging time. A BTMS will continue to do its job in cold weather, but there are a few specific ways fleet managers and drivers can help optimize their efficiency and uptime during the winter months.

EVs should be plugged in whenever possible to allow the BTMS to maintain the battery at operating temperature. Drivers can regulate the use of in-cabin heating, opting for functions with less power draw, like heated seats and steering when possible, and turning off the heater when exiting the vehicle. Keeping the vehicle housed in a garage will also help reduce the impact of extreme weather conditions. Fleets should also pay attention to the diagnostic and maintenance software for battery thermal management systems, as there are tools in place to help customers do necessary preventive maintenance to keep their vehicles running smoothly.

Gina Maria Bonini is the Vice President and General Manager of Advanced Thermal Systems for Modine Manufacturing, where she is responsible for leading the company’s commercial electric vehicle initiative and driving global revenue in the automotive market. Previously, she served Tektronix as the General Manager of the Component Solutions Organization and Technology Solutions Organization. During her 13 years at Tektronix, she held roles of increasing responsibility, including Director of Marketing for the U.S., Canada, and Latin America. Gina holds a BS in chemical engineering from the University of California, Berkeley, and an MS in electrical engineering from Stanford University.

About Modine

At Modine, we are engineering a cleaner, healthier world. Building on more than 100 years of excellence in thermal management, we provide trusted systems and solutions that improve air quality and conserve natural resources. More than 11,000 employees are at work in every corner of the globe, delivering the solutions our customers need, where they need them. Our Climate Solutions and Performance Technologies segments support our purpose by improving air quality, reducing energy and water consumption, lowering harmful emissions and enabling cleaner running vehicles and environmentally-friendly refrigerants. Modine is a global company headquartered in Racine, Wisconsin (USA), with operations in North America, South America, Europe and Asia. For more information about Modine, visit www.modine.com.